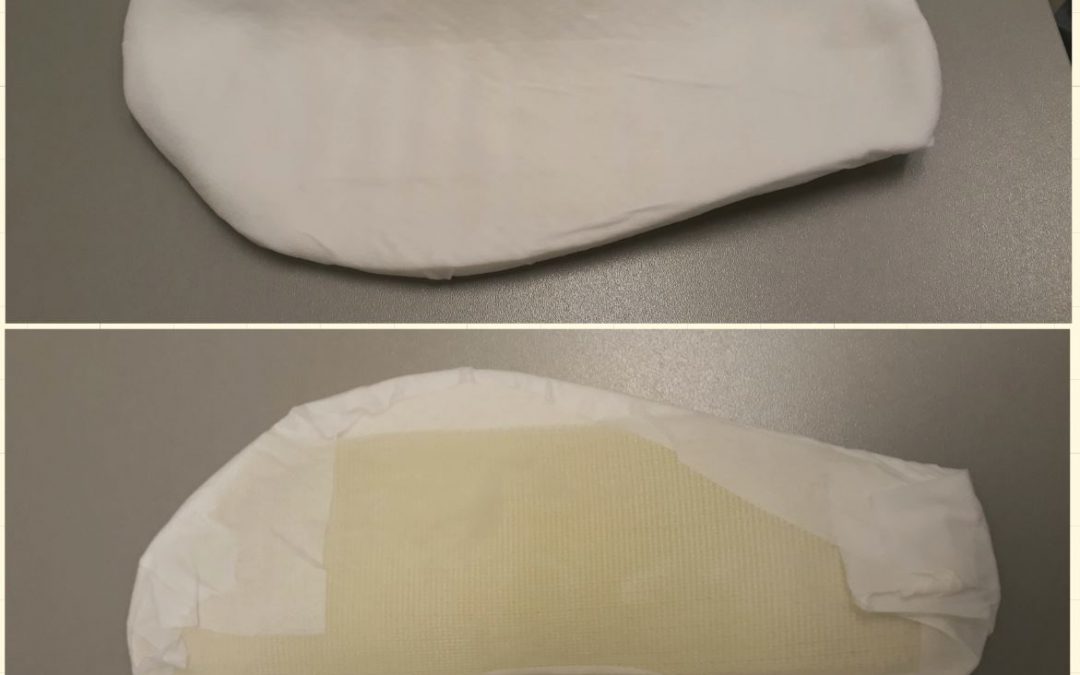

Felt and fiberglass – the combination may result in a sole with

- pressure-optimized contact surface

- stiffened sole with rocker-bottom

which is firmly attached beneath the foot. This minimizes the possibility of application errors. Felt is cut according to the entity concept. It provides support at the relevant points in such a way that, together with recesses, 100% relief of the wound should be achieved. The stiffened sole is made of a fibreglass material used in medicine for splints. To maintain consistent standards, we have named this sole FiF!-mobil®. The trademark is meant to maintain standardisation.

Indication

The indication is found the extent of the necessary offloading capacity. In all forefoot lesions, this can be used to increase the degree of offloading. This is particularly relevant in the case of:

- Lack of function of the big toe (amputation, rupture of the flexor hallucis longus (FHL) tendon).

- Fresh plantar surgical wounds

- Hallux rigidus

Another indication is seen in application errors of other offloading aids. If all other possibilities fail, it can be useful to attach this sole under the foot again and again with each dressing change.

Material

The material is standard in facilities that also do TCC’s.

- Felt, 5 mm thick, 1-2 mm remains when pressed in, and can be cut with paper scissors.

- Fiberglass: material for plaster splints, 3 mm, can also be cut with scissors

- edges are sharp: no contact with the skin without 1 layer of felt in between should be possible

- bonds with water (faster when warm):

- bonding takes 20-30 min. to become stable enough for handling (corrections possible with scissors)

- after 24 h final strength is reached, and correction is possible with an oscillating saw

- Adhesive fleece: resistant to traction in one direction: behind the heel brought to calf

Curvature

The finished sole has 3 curvatures

- Longitudinal curvature

- Preset by curvature mold

- It is somewhat flattened in the first hours of use because the sole is usually put under load before the final strength is reached.

- As a result, the patient adapts the curvature to his gait pattern, and the “roll” is automatically compatible with the gait of the affected person.

- Transverse bending at the edges

- Especially the medial edge follows the contour of the foot

- The resulting “halfpipe” increases stiffness considerably

- Around the heel ball

- A slight edge improves the “automatically” correct position of the sole

Proposed Course

- Cut felt to size

- Placeholders fill gaps

- Attach felt without fixation

- Cut fiberglass to size attach with fleece, spray, fix with packing film

- Attach curvature mold, fixation with packing foil

Break: Patient sits and puts his foot into the hardening sole for 30 min.

- Carefully loosen and finish the Fif!-mobile® sole

- Removal of the placeholders

- Covering with adhesive fleece

- Fixing with adhesive fleece

Sources

The components are readily available as office supplies. The curvature mold can be freely downloaded from thingiverse and printed with a 3D printer. There is a set for smaller printers in which the sole is printed in two parts and then glued together, and a set with whole soles if the print bed is at least 200×250 mm large.

Conclusion

The Fif!-mobil® sole combines a pressure-optimized contact surface with sole stiffening & roll-off sole. It remains reliably “on the man” because it is glued under the foot. It is made in the foot clinic with manageable effort and avoids possible imponderables in the implementation of felting by community nurses.

Course

At present (2023) there are only courses in German. In case of questions concerning language, please contact us using the form below.